Lecture 4. - Assignment

|

Cable Harness Analysis | |

| Whole wiring of a vehicle. | The magnetic field intensity in the wire and in the car body. [Click to see animation.] |

|

Instructor

|

Teaching Assistants:

|

Contents

Purpose of the Assignment

The student will learn the main steps of the finite element method, such as preparing the model (creating or importing geometry), specifying material parameters, boundary conditions, and excitation through a full-wave problem. This example gives a brief insight into the cable harness analysis through an automotive example.

Knowledge needed to solve the problem

- The steps of the finite element method;

- Theoretical knowledge of full-wave fields (for defining materials, excitation);

- Basic knowledge of electric network theory.

Steps to solve the problem

After launching ANSYS Electronics Desktop, open the file CableHarness_Example.aedt using the File [math] \to [/math] Open menu.

To use ANSYS 2D Extractor, ANSYS HFSS and ANSYS Circuit, the Help menu and YouTube videos provide a lot of help.

Defining the Problem

.In this case, the whole problem is pre-defined. The reason for this is to avoid lengthy setup and basically, the purpose of the example is to look at the effect of high-frequency cables for the car body. Thanks to this example, students explain why you need to pay attention to the proper cable routing in vehicles. However, we review the structure of this task.

The problem is split into three parts:

- The analysis of cable (ANSYS 2D Extractor);

- the set up of cable harness electric circuit (ANSYS Circuit);

- and the high-frequency analysis of the car body with cable harness (ANSYS HFSS).

Before and during the run, we briefly review the settings of the problem.

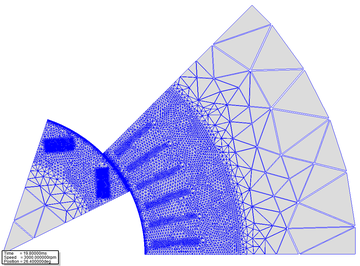

It is important to note that in the previous two examples, adaptive meshing used. However, in the case of a time-dependent (transient) problem, it is not possible to use the adaptive mesh, so we need to define the discretization of the problem with different mesh operations.

Analysis of Cable Parasitics (ANSYS 2D Extractor)

ANSYS 2D Extractor efficiently performs the 2D quasi-static electromagnetic field simulations (ANSYS Q3D Extractor for 3D problems) required for the extraction of RLCG parameters (R - resistance, L - inductance, C - capacitance, G - conductance) from an interconnect structure.

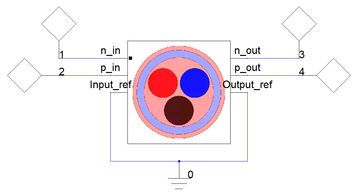

As you can see in the figure, the cable has positive, negative and return veins. The veins wrapped by insulation and the outer sheath.

The simulation frequency is 300 MHz and the result of the analysis is shown in the following tables.

|

| ||||||||||||||||||

|

|

Driving Circuit of Cable Harness (ANSYS Circuit)

The return path is grounded, while a port with 50[math]\Omega[/math] terminal impedance is defined for the negative and positive conductor. The parasitic parameters of the cable veins are coming from the 2D Extractor simulation. The results of this circuit simulation are used as the excitation of finite element simulation.

Car Body with Cable Harness (ANSYS HFSS)

Sett up the solver, run the simulation

At the solver, the end of the time interval of calculation should be defined as well as the time step. In this example, the end time is 15 ms (Stop time) and 0.05 ms (100 time steps per period) is the time step.

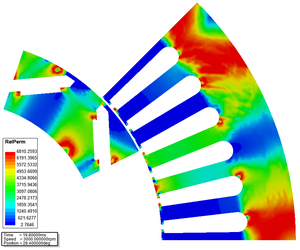

You may also need to set the nonlinear solver, because the [math] {B} - {H} [/math] relation of the stator and rotor steel is nonlinear. In this case, the relative permeability is space dependent, as you can see in Fig. 1.

In order to plot the result at several time instants, it is necessary to specify in which time step we want to save the solution. If we do not do this, the last time step is saved automatically, so the field quantities ([math]\vec{A}; \vec{B}; \vec{H}[/math]; ...) or other derived quantities ([math] \text{loss}, \text{energy}, ... [/math]) can be plot in this instance.

Evaluation of results

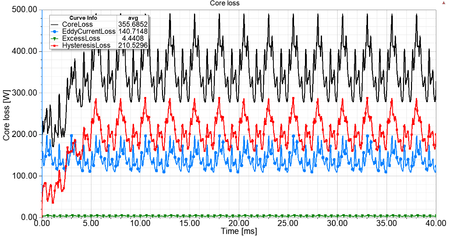

The purpose of this example is to illustrate the source of undesirable phenomena in electric machines. The source of the heat is the loss in the various parts of the machine. We have already met with the eddy current loss in the previous lecture. However, the so-called electric steels has more components for core loss

- [math] p_{\text{vas}} = p_{\text{h}} + p_{\text{c}} + p_{\text{e}} = K_{\text{h}}f(B_{\text{max}})^2 + K_{\text{c}}(f B_{\text{max}})^2 + K_{\text{e}}(f B_{\text{max}})^{1.5} [/math],

where [math]p_{\text{h}}[/math] is the hysteresis loss, [math]p_{\text{c}}[/math] is the eddy current loss, [math]p_{\text{e}}[/math] is the excess loss, [math]K_{\text{h}}, K_{\text{c}}, K_{\text{e}}[/math] is the coefficient of losses, [math]f[/math] is the frequency and [math]B_{\text{m}}[/math] is the maximum of magnetic flux density. Fig. 1 shows the core loss and its components as a function of time.

The other main undesirable phenomenon is the vibration of electric machines. Here, we only deal with the main electromagnetic source of the vibration, the air-gap flux density, which differs from pure sinus, so it has harmonic content (harmonic content hardly depend on the design of machine). According to the Maxwell stress tensor, the tensile force (radial force magnitude) acting on the stator and on the rotor surface is proportional to the square of the normal component of the air-gap flux density. The Maxwell stress tensor can be calculated with the following relationship

- [math]\vec{\sigma} = \frac{1}{\mu_0}\left(\vec{B}\cdot\vec{n}\right)\vec{B} - \frac{1}{2\mu_0}B^2\vec{n}[/math],

where [math]B = \|\vec{B}\|[/math] is the absolut value of magnetic flux density. Fig. 3 shows the force acting on the stator teeth.

| Fig. 1 - The core loss and its components in the function of time. | Fig. 2 - The relative permeability in the stator and rotor core. | Fig. 3 - The variation of teeth force as a function of time. [Click to see animation.] |